- Home>

- Brands>

- Devoe>

- Industrial Paint>

- Epoxy>

- BAR-RUST 235 - PART B (REG) - 0.76L (4:1)

BAR-RUST 235 - PART B (REG) - 0.76L (4:1)

Product Code: DC235C0980-1QT

Product Description :

Bar-Rust 235 is a high performance, multi-purpose, surface tolerant, two-component chemically cured epoxy semi-gloss coating.

Advantages :

- Exceptional corrosion protection

- Suitable for salt & fresh water immersion

- Low temperature cure to 0°F (-18°C), minimum surface application temperature 20ºF (-7ºC)

- Surface tolerant - Good adhesion to damp surfaces

- Self-priming for steel & masonry substrates

- Fast Recoat

- High solids – high film build

Utilisation

For use on properly prepared steel or masonry surfaces including immersion (non-potable water) service. Ideal for structural steel, piping, storage tank exteriors, machinery, and equipment in petroleum refineries, pulp and paper mills, chemical and fertilizer plants, and sewage treatment plants. Performance alternate for Federal Specifications TT-C-550 and TT-C-545. Meets AWWA D102.

Surface preparation

Surfaces must be dry, clean, free of oil, grease, form release agents, curing compounds, laitance, other foreign matter and be structurally sound. Remove all loose paint, mortar spatter, mill scale, and rust. All direct to metal coatings provide maximum performance over blasted surfaces. There are situations and cost limitations which preclude blasting. Bar-Rust 235 was designed to provide excellent protection over less than ideal surface preparation. The minimum standard for nonimmersion service is SSPC-SP2 or ISO8501-1:2007 St2; for immersion service the minimum standard is SSPC-SP6 or ISO8501-1:2007 Sa2. These minimum surface preparation standards apply to steel that has been previously abrasive blasted, coated and deteriorated. Where very rusty surfaces still remain after cleaning use Pre-Prime 167 Sealer before application of Bar-Rust 235. All direct to metal coatings provide maximum performance over near-white blasted surfaces.

New Surfaces:

Steel New steel surfaces should be initially abrasive blasted to near-white metal surface cleanliness in accordance with SSPCSP10 or ISO8501-1:2007 Sa2.5. Blast profile on steel should be at least 2.5 mils (63 microns) in depth and be of a sharp, jagged nature as opposed to a “peen” pattern (typically obtained in shot blasting).

Concrete Block:

Remove loose aggregate and repair voids. Fill with Bar-Rust 235 or Tru-Glaze-WB 4015 blockfiller.

Concrete Floors, Poured Concrete:

Cure at least 30 days. Acid etch or abrasive blast slick, glazed concrete or concrete with laitance. Prime with Pre-Prime 167 or Bar-Rust 235

Galvanized Steel

Remove dirt and oils by solvent cleaning or with Devprep 88 Cleaner or other suitable cleaner followed by a thorough water rinsing. Prime with Devran 203 or Devran 201H epoxy primers for non-immersion. For immersion or severe moisture condition, abrasive blasting is recommended before priming with this product or Devran 201H epoxy primer.

Previously Painted Surfaces

Old coatings should be tested for lifting. If lifting occurs, remove the coating. Otherwise, scuff sand glossy areas and aged epoxy coatings. Clean aged epoxy or urethane coatings with Devprep 88 Cleaner. Remove cracked and peeling paint. Prime bare areas with appropriate primer. If thinning is required, use International GTA007 only when used over aged alkyd coatings.

Recommanded systems

The following primers are recommended for Bar-Rust 235:

Bar-Rust 235

Cathacoat 302H

Cathacoat 302HB

Cathacoat 304L

Cathacoat 304V

Cathacoat 313

Cathacoat 316

Devran 201H

Devran 203

Pre-Prime 167

Tru-Glaze-WB 4015

The following topcoats are recommended for Bar-Rust 235:

Devthane 349QC

Devthane 359

Devthane 359H

Devthane 378

Devthane 378H

Devthane 379

Devthane 379H

Devthane 389N

Devthane 389H

Application conditions

Required tools

Airless spray

Recommended

Tip Range 19-25 thou (0.48-0.63 mm) Total output fluid pressure at spray tip not less than 3000 psi (211 kg/cm²)

For airless spray application: Use an airless spray pump capable of 3,000 psi (207 bars) and .019” to .025” tip size will provide a good spray pattern. Ideally, fluid hoses should not be less than 3/8” ID and not longer than 50 feet to obtain optimum results. Longer hose length may require an increase in pump capacity, pressure, and/or thinning.

Air spray

suitable

For air spray application: Use a fluid tip of .070'' or larger, a professional grade conventional gun and an air cap with good break-up. The fluid pressure should be kept low with just enough air pressure to get good break-up of the coating. Excessive air pressure can cause over-spray problems.

Brush & roller

suitable

How to use

Mixing

Material is supplied in two containers as a unit. Always mix a complete unit in the proportions supplied. Once the unit has been mixed it must be used within the working pot life specified.

(1) Agitate Base (Part A) with a power agitator.

(2) Combine entire contents of Curing Agent (Part B) with Base (Part A) and mix thoroughly with power agitator.

Thinning is not normally required or desired; however, at extreme environmental conditions, small amounts (15% or less by volume) of International GTA220 can be added depending on local VOC and air quality regulations. When using Bar-Rust 235 over aged alkyds, use International GTA007. Any solvent addition should be made after the two components are thoroughly mixed.

Mix ratio

4 part(s) : 1 part(s) by volume

Working pot life

23°F (-5°C) 41°F (5°C) 59°F (15°C) 77°F (25°C)

6 heures 5 heures 5 heures 4,5 heures

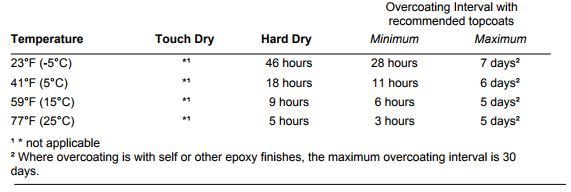

Drying time

Cleaning tools

Clean all equipment immediately after use with International GTA415. It is good working practice to periodically flush out spray equipment during the course of the working day. Frequency of cleaning will depend upon amount sprayed, temperature and elapsed time, including any delays.

Warning

Work stoppages : Do not allow material to remain in hoses, gun or spray equipment. Thoroughly flush all equipment with International GTA415. Once units of paint have been mixed they should not be resealed and it is advised that after prolonged stoppages work recommences with freshly mixed units.

All surplus materials and empty containers should be disposed of in accordance with appropriate regional regulations/legislation.

Bar-Rust 235 may yellow during application and cure if exposed to the combustion by-products of improperly vented fossil fuel burning heaters.

Off White, custom and ready-mix colors

| Category : | Industrial paint |

| Brand : | International |

| Manufacturer : | AkzoNobel |

| Physical state : | Liquid |

| Base : | alkyd |

| Numbre of component : | 2 |

| Composition : | Surface tolerant epoxy |

| Binder : |

|

| COV : | 2.43 lb/gal (292 g/lt) EPA Method 24 |

| Provenance : |

|

| Durability : |

|

| Covering power : | 182 sq.ft/US gallon at 6 mils d.f.t and stated volume solids 4.50 m²/liter at 150 microns d.f.t and stated volume solids |

| Film thickness requirement wet : | 5,9-11,8 mils (147-294 microns) wet |

| Film thickness requirement dry : | 4-8 mils (100-200 microns) dry |

| Diluent : | GTA220 ou GTA007 |

| Drying time (touch dry) : | N/A |

| Drying time (dust free) : | N/A |

| Drying time (before recoating) : | 3 h @ 25°C, 6 h @ 15°C, 11 h @ 5°C, 28 h @ -5°C |

| Drying time (full curing) : | 5h à 46h depending on temperature |

| Odor : |

|

| Aspect : | tinted liquid |

| Gloss : | Semi-gloss |

| % solid volume : | 68% ± 2 |

| % solide weight : |

|

| Density : | 1.45 |

| Viscosity : |

|

| Heat resistance : |

|

| Flammability : | Flammable |

| Flash point : | Part A 100°F (38°C); Part B 100°F (38°C); Mix 100°F (38°C) |

| Storage : |

|

| Preservation : |

|

| Cleaning tools : | GTA220 |

| Compatibility : |

|

| Emergency spill information : |

|

3.79L (3.03L Part A + 0.76L Part B)

18.9L (15.14L Part A + 3.79L Part B)